ภาพรวม

Infrared lenses refer to lenses used to reflect, refract, and transmit infrared light. It uses unique physical properties to realize the control of infrared light, so it is of great significance in the field of infrared optics. Due to the issue of transmittance, there are only a few materials available for use in the infrared wavelength range, such as Si, Ge, ZnSe, ZnS, and MgF2.

Generally, the Knoop hardness of visible light glass is between 300-700. The harder the material is, the longer it takes to grind and polish the optical lens. Among the glass materials commonly used in the field of infrared thermal imaging, the hardness of Ge is 780 , while the hardness of Si has reached 1150. Compared with visible light, the hardness of infrared thermal imaging optical lens is much higher, so the difficulty of its grinding process and working hours are much larger than that of visible light. Although both Ge and Si are hard materials, but also very brittle. This makes them prone to breakage during the production and processing processes, leading to a decrease in yield. Therefore, strict requirements are placed on the processing techniques; in addition, the cost per gram of these materials is relatively high, making the processing risks significant.

Property

1.hard

2.brittle

3.the material has a high cost

The Knoop hardness test is particularly suitable for testing materials that are hard and brittle. It can also be used to determine the effective depth of surface hardening layers. It is applicable for testing the hardness of small parts, small areas, thin materials, fine wires, hardness near blade edges, plating layers, and dental materials.

common material

Ge material

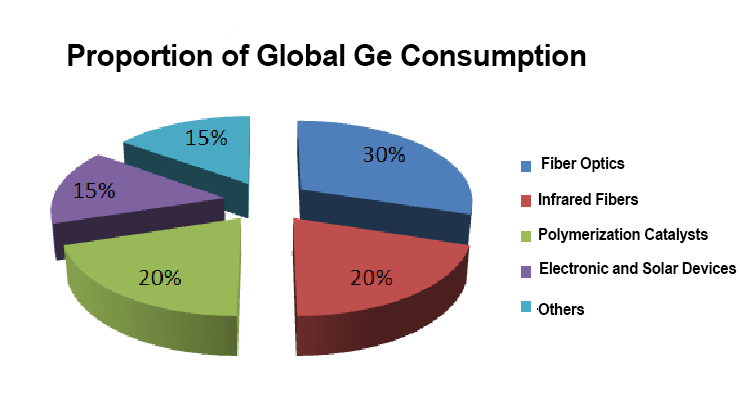

Ge is an extremely important material for infrared optical lenses, but because of its scarcity on the earth and high price, many companies gradually adopt other low-cost infrared optical materials on a large scale. With the development of the infrared industry, the demand for infrared optical materials is expanding, and the research and development and production of infrared optical materials have become key factors of concern for many specialized companies.

The chemical symbol of germanium: Ge, is a grayish-white metalloid, shiny, hard, belonging to the carbon family, and has obvious non-metallic properties. Ge has stable chemical properties and does not react with air or water vapor at room temperature.

Ge glass has good light transmission performance at 2-16um. By depositing optical coatings on Ge glass, its transmittance can be significantly increased while reducing the reflectivity on the surface of the glass. However, Ge glass cannot transmit light in the visible light wavelength range.

Ge has a content of approximately 0.0007% in the Earth’s crust, making it one of the most dispersed elements in the crust. There are few concentrated germanium ores. A significant amount of Ge exists in various metal silicate ores, sulfide ores, and different types of coal in dispersed form; certain copper, iron, sulfide ores and silver ores also contain Ge; Trace amounts of Ge can be found in rocks, soils, and spring water; limited quantities of Ge are present in many plants. Ge is widely used in the fields of electronics, optics, chemical industry, biomedicine, energy, and other high-tech industries.

As an infrared material, Ge can be used in LWIR and MWIR ranges. In the LWIR range, it is the positive lens in the achromatic doublet lens; while in the MWIR, it is the negative lens in the achromatic doublet lens. This is due to the difference in its dispersion characteristics in the two wavelength ranges. In the MWIR range, Ge is very close to its low absorption band, resulting in rapid changes in its refractive index and significant dispersion. This makes it suitable as a negative power element in an achromatic doublet lens.

Ge is a crystalline material that can be produced in the form of single crystals or polycrystals. Depending on the growth process, single crystal Ge is more expensive than polycrystalline Ge. The refractive index of polycrystalline Ge is not uniform enough, primarily due to impurities at grain boundaries, which can affect the image quality on the FPA. Therefore, single crystal Ge is preferred. At high temperatures, Ge material becomes absorptive, and its transmission ratio approaches zero at 200°C.

Ge has a high Knoop hardness and is often used in infrared systems that require high intensity. Due to its high refractive index, anti-reflection coatings are often applied to Ge, with commonly used wavelength ranges of 3-12 μm or 8-12 μm. The transmittance of Ge decreases with increasing temperature, and strictly speaking, its optimal operating temperature is below 100 degrees Celsius. When it is applied to a system that is sensitive to weight requirements, designers should consider the high-density characteristics of Ge. The ratio of lens size to thickness should adhere to processing proportions, while the weight should meet the design requirements.

The temperature coefficient of refractive index (dn/dT) is used to measure the change in refractive index with temperature. For most infrared materials, the dn/dT is several orders of magnitude higher than that of visible light glass, resulting in a significant change in refractive index. The density of a substance is almost always inversely proportional to temperature, meaning that the density decreases as the temperature increases. Therefore, the refractive index decreases with increasing temperature.

The dn/dT of Ge is 0.000369C, while the dn/dT of ordinary glass is 0.000360C. This can cause significant focal shift with temperature variations, often requiring some form of athermalization technique.

Si material

Si is a crystalline material that is similar to Ge. Single-crystal Si is a chemically inert material with high hardness and insolubility in water.

It has good light transmission performance both in the 1.2-7μm wavelength range and in the far-infrared wavelength range of 30-300μm, which is a unique characteristic not found in other infrared materials.

Si single-crystal is commonly used as a substrate for 3-5μm mid-wave infrared optical windows and optical filters. Due to its good thermal conductivity and low density, it is often used in the production of laser mirrors and occasions that are sensitive to volume and weight.

The refractive index of Si is slightly lower than that of Ge, but it is still sufficiently high for controlling aberrations. Additionally, Si has relatively low dispersion. Si can be diamond turned.

One of the downsides of silicon and some other crystalline materials is that they are brittle and fragile.

ZnS

ZnS is a chemically inert material with the characteristics of high purity, insoluble in water, moderate density, and easy processing. It is a material commonly used in MWIR and LWIR bands.

ZnS is a material with good refractive index uniformity and consistency, and has good image transmission performance in the 8-12 μm band, but it begins to partially absorb after 10 μm. The material also has high transmittance in the mid-infrared, but absorption and scattering increase as wavelengths become shorter. Compared with ZnSe, ZnS has high hardness, twice the fracture strength of ZnSe, and strong resistance to harsh environments.

ZnS is generally rust-yellow and translucent to visible light. ZnS made by hot pressing can be transparent to visible light. Transparent ZnS can be used to fabricate multispectral windows and lenses from visible to LWIR bands.

ZnS is a transparent infrared transparent material. It has stable transmittance in the infrared band and has excellent optical properties, and is one of the main materials for making infrared windows. In the infrared manufacturing process, ZnS can be used by thin film deposition techniques to increase its infrared reflection effect. ZnS materials are widely used in the manufacture of infrared sensors, optical lenses, thermal imagers, fairings and infrared optical components.

ZnSe

ZnSe is similar to ZnS in many respects. Its refractive index is slightly higher than that of ZnS, and its structure is not as strong as ZnS. Therefore, a thin layer of ZnS is sometimes deposited onto a thick ZnSe substrate for environmental durability reasons. Compared with ZnS, the most significant advantage of ZnSe is its extremely small absorption coefficient.

ZnSe is a commonly used infrared reflective film material, and its reflection wavelength range is 2-14 μm. It has the advantages of high transmittance, simple preparation process, good corrosion resistance and wear resistance. ZnSe film can also be used with other types of infrared lens materials to increase the effect of infrared reflection. ZnSe lenses are used in infrared sensors, thermal imagers, and various infrared control systems.

Because ZnSe has a low absorption coefficient and high thermal expansion coefficient, it is usually used as the base material of reflectors and beam splitters. However, since ZnSe is relatively soft (Knoop hardness of 120) and easy to scratch, it is not recommended to be used in harsh environments. Pay attention to uniform force when holding and cleaning, and it is best to wear finger cots or gloves.

Fluoride

MgF2

MgF2 is also a crystalline material. Its crystalline material transmits the spectral band from UV to MWIR. MgF2 can be produced by crystal growth or “hot pressing”, resulting in a milky glassy material. It transmits well in the MWIR band, but there may be unwanted scatter, causing loss of contrast and off-axis stray light.

CuF2

CuF2 is a common infrared absorbing material. It can absorb the infrared band of 2-14μm, and can reduce the transmittance in the visible spectrum region at the same time. Therefore, infrared filters made of CuF2 can be used in anti-glare and thermal imaging systems to filter out visible light and infrared interference to achieve better infrared detection results. CuF2 materials can also be used in optical lenses and infrared windows and other fields.

CaF2

CaF2 has a high transmittance between ultraviolet and mid-infrared (250nm~7μm), so it is widely used in the manufacture of prisms, windows and lenses, etc. In some applications with a wide spectral range, it can be directly used without coating. In particular, it has low absorption and high laser threshold, which is very suitable for excimer laser optical system.

BaF2

The light transmittance range of BaF2 crystal is wide, and the light transmittance is good in the wavelength range of 0.13μm~14μm. The properties of single crystal and polycrystalline are basically the same, and the material is difficult to produce single crystal, so the price of single crystal is twice that of polycrystalline. BaF2 crystal is an ideal material for making optical components such as various optical windows, prisms and lenses. It can be used in infrared power distribution cabinet windows, Fourier gas analysis windows, oil and gas detection, high-power lasers, optical instruments, etc.

Sapphire

The composition of sapphire is aluminum oxide, which is blue due to the trace elements titanium (Ti4+) or iron (Fe2+). In fact, the gem-grade corundum in nature is called sapphire except for the red one called ruby, and other colors such as blue, light blue, green, yellow, gray, colorless, etc.

Sapphire is an extremely hard material. It transmits light from deep UV to MWIR. A unique property of sapphire is its very low thermal emissivity at high temperatures. This means that at high temperatures the material emits less thermal radiation than other materials. Sapphire can be used to make cavity windows that withstand high temperatures and are suitable for passing windows in the infrared band.

The main disadvantage of sapphire is that its hardness makes optical processing difficult. Another similar material is called spinel. Spinel is similar in effect to hot-pressed sapphire and can be used in place of sapphire. Spinel stone also has high dispersion.

The application fields of sapphire mainly involve LED substrate materials, consumer electronics and military applications. It is an important material to support the development of energy conservation, environmental protection, new generation information technology, new energy vehicles and other industries.

โฟเนียร์: ผลิตภัณฑ์ออปโตอิเล็กทรอนิกส์

โฟเนียร์: ผลิตภัณฑ์ออปโตอิเล็กทรอนิกส์