Descripción general

Infrared focal plane detector is the core component of the thermal imaging system and the key to detecting, identifying and analyzing the infrared information of objects. It has a wide range of applications in military, industry, transportation, security monitoring, meteorology, medicine and other fields.

Infrared focal plane detectors can be divided into cooled infrared focal plane detectors and uncooled infrared focal plane detectors. The advantages of cooled infrared focal plane detectors are high sensitivity, ability to distinguish more subtle temperature differences, and longer detection distance. It is mainly used in high-end military equipment. The uncooled infrared focal plane detector does not need a refrigeration device and can operate at room temperature. It has the advantages of small size, light weight, low power consumption, long life, low cost, and quick start-up. Although it is not as sensitive as cooled infrared focal plane detectors, the performance of uncooled infrared focal plane detectors can meet the technical requirements of some military equipment and most civilian fields.

Principio de funcionamiento

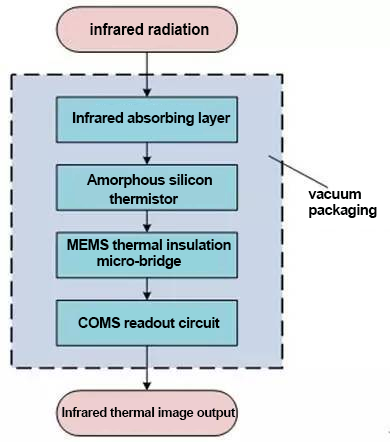

The uncooled infrared focal plane detector is composed of many MEMS (micro-electromechanical systems) micro-bridge structure pixels arranged two-dimensionally repeatedly on the focal plane, and each pixel measures the thermal radiation at a specific incident angle. Basic principle:

a): Infrared radiation is absorbed by the infrared absorbing layer in the pixel to cause a temperature change, thereby changing the resistance value of the amorphous silicon thermistor;

b): The amorphous silicon thermistor is supported above the silicon substrate through a MEMS thermal insulation micro-bridge, and is connected to the COMS readout circuit fabricated on the silicon substrate through a supporting structure;

c): The CMOS circuit converts the resistance value change of the thermistor into a differential current and performs integral amplification. After sampling, the gray value of a single pixel in the infrared thermal image is obtained.

Key Parameters Affecting Performance

1. Response Rate:

It refers to the ratio of the output signal to the input infrared radiation power. The greater the response rate, the better the performance of the detector.

2. Response Wavelength Range:

Uncooled (heat-sensitive) infrared detectors have no selectivity to the response wavelength, and show the same sensitivity to incident light of various wavelengths. Generally working at room temperature, the sensitivity is low, and the response time is also long.

3. Noise:

Noise comes from some basic physical processes in the infrared detector, even in the absence of incident radiation, there will be noise. Noise will affect the detection accuracy of the infrared detector, the smaller the noise, the better the performance of the detector.

Detector noise mainly includes dark current noise and photoelectron noise. The main method to reduce the dark current noise is to lower the temperature from room temperature to liquid nitrogen temperature, and the dark current noise can be reduced by 50%.

4. Signal-to-noise Ratio(SNR):

It refers to the ratio of the signal output voltage generated by the incident radiation to the noise voltage output at the same time. The higher the signal-to-noise ratio of the device, the lower the noise, and vice versa. Por lo tanto, the higher the signal-to-noise ratio, the better.

5. Noise Equivalent Power:

When the output voltage generated by the incident radiation is exactly equal to the noise voltage of the detector itself, the incident radiation power at this time is called the noise equivalent power. The lower the noise equivalent power of the detector, the better.

6. Noise Equivalent Temperature Difference:

This refers to the minimum temperature difference that the infrared detector can detect, the smaller the value, the better.

7. Detection Rate:

It is the reciprocal of the noise equivalent temperature difference. The higher the detection rate, the better.

Solicitud

Uncooled infrared detectors have a very wide range of applications in military and commercial fields:

1. Military field

Applications in the military field include Thermal Weapon Sight (TWS), Portable Vision Enhancement, Driver’s Vision Enhancer (DVE), Remote Weapon Station (RWS), Unmanned Aerial Vehicle (UAV), Unmanned Ground Sensor(UGS), Observation Command Vehicle, Rocket Guidance and Control, etc..

2. Thermal imaging temperature measurement field

Thermal imaging temperature measurement is used for predictive maintenance, such as detecting abnormal heating areas through infrared thermal cameras on power transmission lines, power generation equipment, and mechanical equipment, which can prevent major shutdowns and accidents. In terms of building inspection, it is used to detect the insulation effect of houses, wall facades, hollowing, water seepage and mildew, etc.. Other thermography applications include product development, electronics manufacturing, medical temperature measurement and process control, etc., as shown in the figure on the right.

3. Commercial vision enhancement field

The main applications of commercial vision enhancement include fire fighting, vigilancia, automotive and maritime infrared vision enhancement, etc., as shown in the left figure. It mainly uses the advantages of infrared imaging without external light source, strong ability to penetrate smoke, long range, strong imaging contrast, etc., to effectively supplement human vision.

4. Consumer Electronics

Due to the wide application and extremely high penetration rate of visible light image sensors in consumer electronics products such as mobile phones, people have high expectations for the application of infrared imaging in consumer electronics. The large-scale application of infrared thermal imaging technology in consumer electronics is currently limited mainly by cost and volume. Actualmente, FLIR and Seek Thermal have launched consumer-grade thermal imaging equipment, which also makes people look forward to more applications of infrared thermal imaging sensors in the field of consumer electronics.

Fronir: Productos optoelectrónicos

Fronir: Productos optoelectrónicos